| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : AMG

Certification : ISO9001

Place of Origin : CHINA

MOQ : 3-10PCS

Payment Terms : T/T/Credit Card

Supply Ability : 30000-100000pcs per month

Delivery Time : 5-12 working days

Packaging Details : Plastic tube

Name : 3 Flute Carbide Shank Relief End Mill AlTiCrN Coated for Mold Steel

Coating : AlTiCrN/AlTiN/ZrN/CrN

Application : Mold Steel

Shank precision : h6

Material : Carbide

OEM/ODM : Available

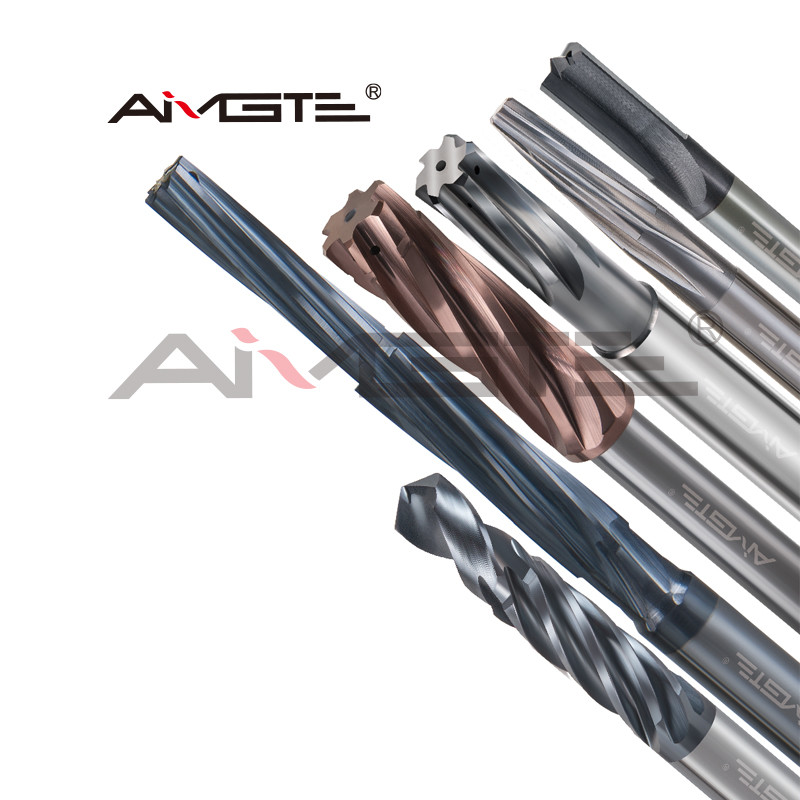

3 Flute Carbide Shank Relief End Mill AlTiCrN Coated for Mold Steel Die Casting High Feed Flat Bottom CNC Milling Cutter

Introduction:

Our 3-flute corner relief end mill is precision-engineered for high-performance machining of hardened mold steels (HRC 50+) and die-casting alloys. Featuring an advanced AlTiCrN nano-coating and specialized corner relief geometry, this carbide end mill delivers exceptional tool life and surface finish in deep cavity milling, mold base machining, and other demanding applications.

The unique flat bottom design with relieved corners prevents tool rubbing during side-wall machining, while the 3-flute configuration optimizes chip evacuation and reduces vibration – making it the ideal solution for high-speed, high-feed CNC operations.

Features:

True corner relief design eliminates interference in deep pockets

3-flute asymmetric edge reduces harmonics for smoother cuts

30° helix angle balances chip removal and tool strength

Flat bottom (0.1mm land) ensures precise floor finishing

Japanese ultra-fine carbide (0.4μm grain) for maximum edge retention

AlTiCrN nano-coating (3,800HV) with superior heat resistance (up to 1,100°C)

Polished flutes minimize material adhesion in gummy alloys

✓ 5× longer life vs standard TiN-coated tools in H13 steel

✓ 20% higher feed rates enabled by optimized chip load

✓ Ra 0.4μm surface finish achievable in finishing passes

✓ Reduced power consumption through efficient cutting geometry

Diameter range: 1-20mm (0.039"-0.787")

Cutting lengths: 3×D to 10×D

Shank configurations: Straight, Weldon, HSK

Special geometries: Variable helix, neck relief

Advantages:

For CNC Programmers:

Pre-optimized speed/feed parameters for common mold steels

Reduced tool deflection in deep reaches

Compatible with trochoidal milling strategies

For Production Managers:

40% faster machining vs conventional 4-flute end mills

Predictable wear patterns enable tool life monitoring

Standardized regrinding preserves geometry

Typical Applications:

① Mold & Die Manufacturing

Core/cavity machining in H13, P20, S7 steels

EDM electrode roughing

② Die Casting Production

Aluminum/Magnesium die mold maintenance

Overflow pocket milling

③ Automotive Tooling

Forging die machining

Trim die maintenance

④ General Precision Engineering

Titanium medical component pockets

Graphite electrode milling

Detailed Pictures:

Our workshop:

Promotion policy:

To help you experience our premium products, we’re excited to offer the following exclusive promotions for first-time buyers:

1.Free Test Samples

Get free samples (total value ≤ $20 USD) when you cover the international shipping cost.

Perfect for evaluating our product quality and performance risk-free.

2.$50 USD Discount on First Order

New customers can enjoy a $50 discount on the first order of $500 or more.

A great way to start our partnership with extra value!

Other products:

FAQ:

1. Are you a manufacturer or trading company?

We are a professional manufacturer of carbide tools which established in 2017.

2. Which CNC grinding machine do you use?

All of our carbide tools are produced by imported WALTER grinding machines.

3. Which shipping method do you usually use?

We usually send goods by express like FedEx, UPS, DHL, TNT, EMS, ETC.

We also can send products to your shipping agent in China.

|

|

8.6mm 3 Flute Carbide Shank Relief End Mill AlTiCrN Coated for Mold Steel Die Casting High Feed Flat Bottom CNC Milling Cutter Images |